We’ve made it our mission to inspire a love of tea. We inspire love with our passion for flavour, our dedication to quality and our commitment to showing kindness to every single person in our supply chain, and the communities they belong to. We endeavour to show kindness to; our tea growers, as we honour and respect every worker across the manufacturing process; the tea industry, as we join the ethical tea partnership to ensure tea isn’t just enjoyed but protected too; and people around the world, as we pledge our support to those living in the big cities and tiny villages across our network. To provide moments of happiness in all aspects of the society, achieve a greater value through hard work and public service; finally heading towards supreme humanity.

Withering refers to the wilting of fresh green tea leaves. The purpose of withering is to reduce the moisture content in the leaves and to allow the flavor compounds to develop. Freshly plucked leaves are laid out in a series of troughs and subjected to hot air forced from underneath the troughs. During the course of withering, the moisture content in the leaf goes down by about 30%, making the leaf look limp and soft enough for rolling. Additionally, the volatile compounds in the leaf, including the level of caffeine and the flavors, begin to intensify. A short wither allows the leaves to retain a greenish appearance and grassy flavors while a longer wither darkens the leaf and intensifies the aromatic compounds.

Fixing or “kill-green” refers to the process by which enzymatic browning of the wilted leaves is controlled through the application of heat. It is held that the longer it takes to fix the leaves, the more aromatic will be the tea. Fixing is carried out via steaming, pan firing, baking or with the use of heated tumblers. Application of steam heats the leaves more quickly that pan firing, as a result of which steamed teas taste ‘green’ and vegetal while the pan-fired ones taste toasty. This procedure is carried out for green teas and yellow teas.

Oxidation results in the browning of the leaves and intensification of their flavor compounds. From the moment they are plucked, the cells within the tea leaves are exposed to oxygen and the volatile compounds within them begin to undergo chemical reactions. It is at this stage that polyphenolic oxidase, including theaflavin and thearubigin, begin to develop within the leaves. Theaflavins lend briskness and brightness to the tea while thearubigins offer depth and fullness to the liquor that’s produced. Here, withered and rolled leaves are spread out on long shelves and left to ferment for a fixed period of time, depending on the type of tea being made. To halt or slow down oxidation, fermented leaves are moved to a panning trough where they are heated and then dried.

Rolling involves shaping the processed leaves into a tight form. As a part of this procedure, wilted/fixed leaves are gently rolled, and depending on the style, they are shaped to look wiry, kneaded, or as tightly rolled pellets. During the rolling action, essential oils and sap tend to ooze out of the leaves, intensifying the taste further. The more tightly rolled the leaves, the longer they will retain their freshness.

In order to keep the tea moisture-free, they are dried at various stages of production. Drying enhances a tea’s flavors and ensures its long shelf-life. Also, drying brings down the tea’s moisture content to less than 1%. To dry the leaves they are fired or roasted at a low temperature for a controlled period of time, typically inside an industrial scale oven. If the leaves are dried too quickly, the tea can turn abrasive and taste harsh. Some teas are subjected to aging and fermentation to make them more palatable. Some types of Chinese Pu-erh, for example, are aged and fermented for years, much like wine.

After the leaves are dried they are taken to shifting which is the process that separates the tea into their grades. The dried tea is put through a FIBRE MAT which removes the fibers in the tea. It has a few rolling pins charged with static electricity which attracts the fiber from the leaves. The tea is then put into the MIDDLETON MACHINE which is the first stage of sorting. The procedure in which the tea is sorted differs from each factory after this stage. Before being packed the teas are sent through WINOWER and COLOUR SORTER.

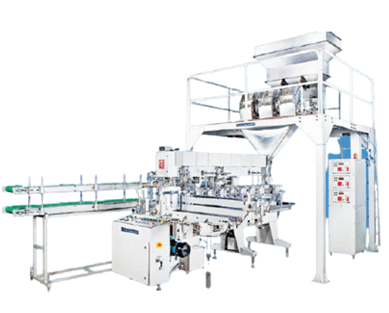

Equipped with a contemporary factory that prcesses over 11 million kilos of tea per annum, the factory is well appointed with an assortment of sophisticated machinery. From tea cleaning, blending to packing facilities, the factory complies with state-of-the-art mechanisms and processes. It also hosts an in-house tea room and laboratory designed for chemical & microbiological analysis.